Aluminum Glazing Extrusions

System Overview

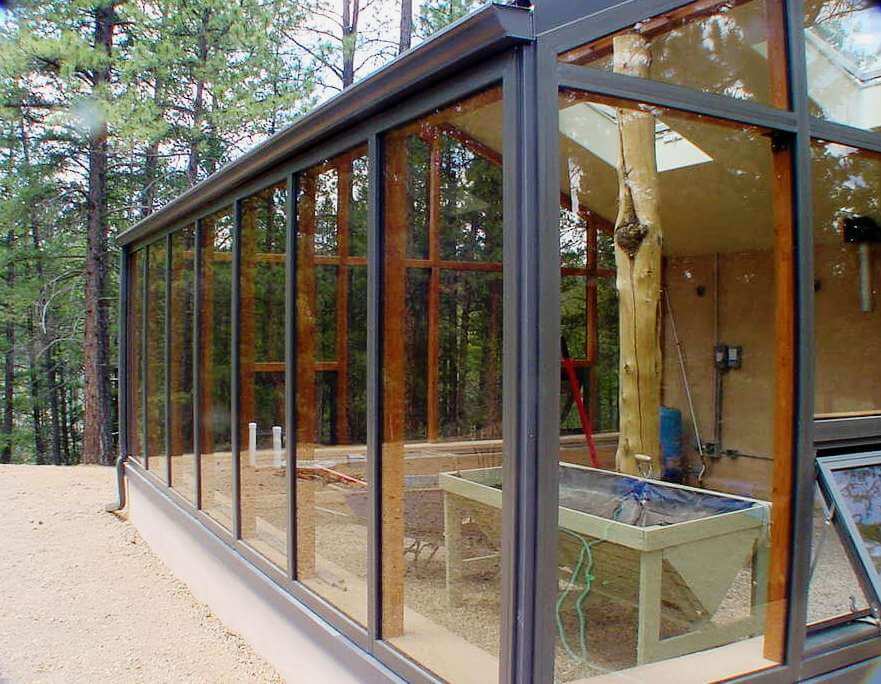

An aluminum glazing system is made of specific extrusions for glass or any solid transparent sheathing such as multi-wall polycarbonate panels, lexan, Plexiglas, or acrylic sheets

Durable Design

Linear Clamp System

Versatile Compatibility

Need Help Deciding?

If you are unsure about building with an aluminum glazing system, contact Ralph for details and expert guidance on your project

Glazing Application Categories

Vertical Applications

- Wall glazing systems

- 45° miter corner joints

- Perimeter assembly top & bottom

Sloped Applications

- Roof glazing systems

- Bevel cap at bottom perimeter

- Same base bar assembly

Assembly Selection Guide

Three Essential Profile Types

- Perimeter Assembly

- Available in 3 heights

- 1 inch, 5/8 inch, 1/4 inch

- Uses flat cap design

- 2 13/16 inches wide

- Mullion Assembly

- Accepts all 3 thicknesses

- 3 1/8 inches wide

- Same cap as Perimeter

- Joins between posts

- Purlin Assembly

- For roof applications

- Sits horizontally on purlins

- Uses bevel cap

- Divides glazing rows

EDPM Glazing Rubber

Structural Requirements

Important Note

3 Inch Surface

Suitable Support Structures

Wood Construction

- Glue-lam beams

- 3 by 6 to 3 by 8 rafters

- 3 by 3 posts

- Double 2 by framing

- Laminated rafters and posts

Other Materials

- Steel rectangular tubes

- Sized to meet local snow loads

- Sized to meet local wind loads

Wood Protection Recommendation

Exposed wood beams should be stained and sealed with two coats of sealer. This keeps the wood long lasting and protects it from UV damage.

Installation Guidelines

Pre-Drilling Requirements

Base Bars (7/32" bit):

Cap Bars (9/32" bit):

Weep Holes & Setting Blocks

Weep Holes (3/16" bit):

Setting Blocks:

Glazing Size Specifications

Pre-Drilling Requirements

- Measure center to center of base screw track

- Glazing must rest flat on EDPM rubber

Best Practice

Measure from: Outer edge of EDPM rubber

Side to side: Full bay width

Height: Setting block to top rubber edge

Installation Procedures

Start with Top Perimeter Bars

Use a string line from end to end. Ensure bar is even and equally distant from top corners. Caulk back side where needed. Miter top corners at 45°.

Install Side Base Bars

Make sure sides are square with frame and top Perimeter bar. Miter top corners and caulk the splice.

Install Vertical Mullion Bars

Place onto rafters. Butt top of each Mullion to inside top of Perimeter bar. Align bottom with lower Perimeter bar.

Install Purlin Base Bars

Fill screw holes with clear silicone. Position between Mullion bars with notched ends overlapping Mullion gutter edge by 1/8" to 1/4".

Flashing & Leak Prevention

Flashing is Required

Flashing must be used with any aluminum glazing system. Flashing at the top, bottom, and sides is project specific and recommended for a leak proof installation.

Bottom Flashing

Run sill flashing continuously under bottom Perimeter base bar and vertical Mullion. Overlap 4-6" with silicone caulk.

Top Flashing

Run continuous flashing over top Perimeter cap, crease downward. Ridge cap covers top bar flashing for double layer protection.

Side Flashing

Clamp continuous flashing between Perimeter base bar and cap. Bend to rake at outer edge of rafter or structure end.

Professional Installation Benefits

Waterproof

Long Lasting

Long Lasting

Waterproof